Featured Products

12GHz Micro BNC Range

Our Micro BNC core range offers a cost effective solution in a variety of profile options, including cable connectors. With the full precision 12GHz capability and small profile, these conenctors are perfect for new designs.

Xtensa CXP Repeater Range

The Xtensa CXP-12 repeater range allows the user to use the full potential of CXP-12, whilst also being able to extend the length of the Coaxial Cables.

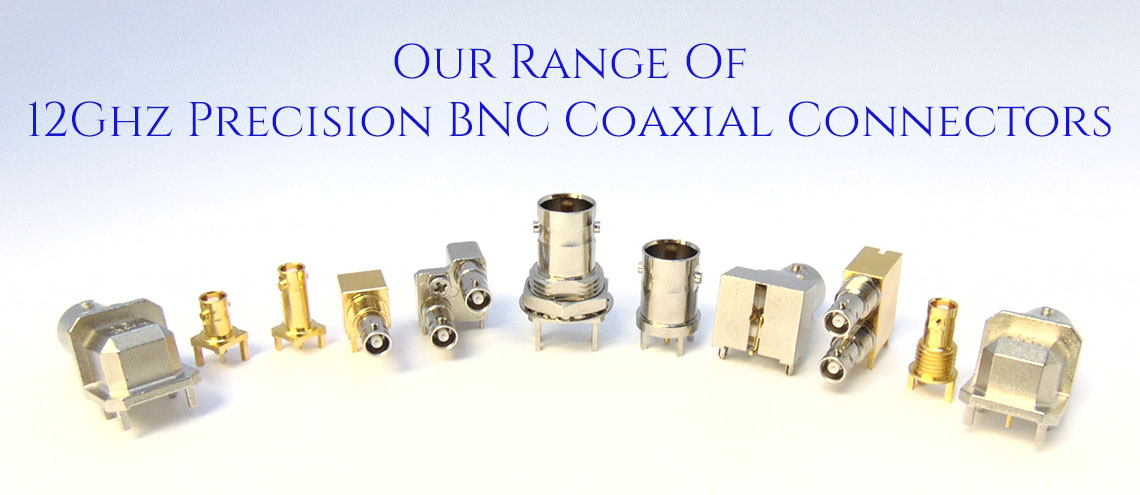

12GHz BNC Connectors

Our range of 12GHz BNC Connectors provide a robust design solution that offer future ready interconnection modules for your new and existing designs.

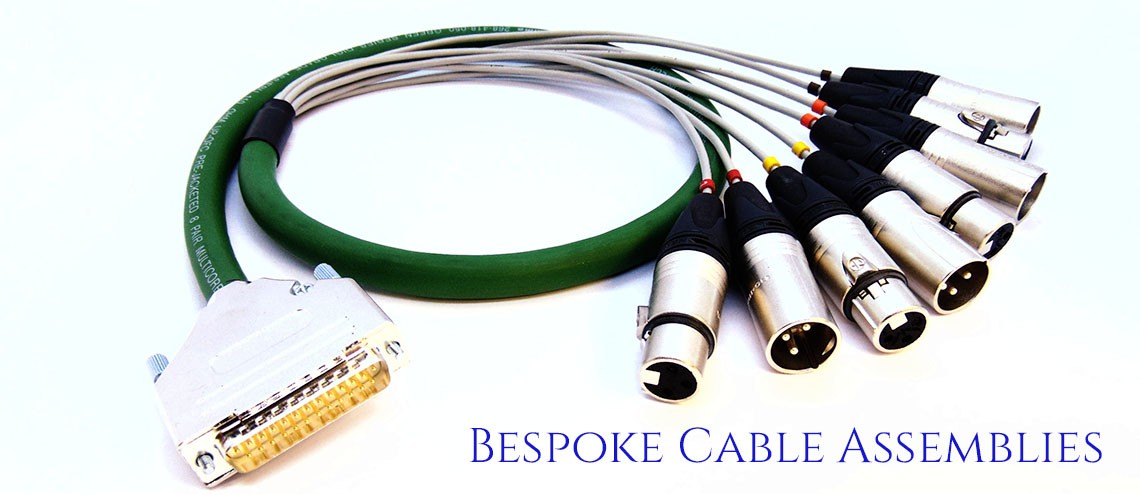

Bespoke Cable Assemblies

Specialists in Coaxial Cable assemblies, Cambridge Electronic Industries are happy to offer bespoke cable assemblies and looms to your design, using leading manufacturers components.

Stay Connected and Follow Us

Follow Us for the Latest Updates

Join us on these social media platforms to see the latest news and products from Cambridge Electronic Industries

Stay Connected

Sign up to stay informed of our upcoming product releases and other information.